The Advantages of Using Hollow Tubes in Construction

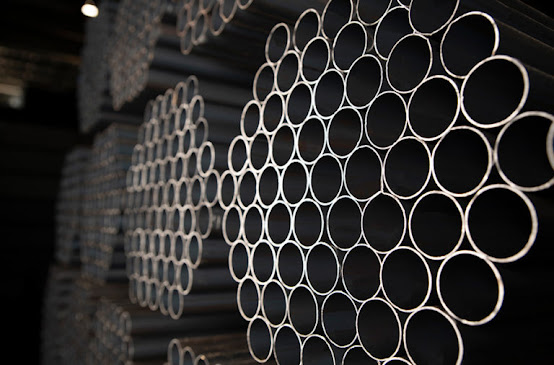

In the world of construction, selecting the right materials is vital to ensure the longevity and safety of a building. One material that has gained popularity over the years is the hollow tube. Hollow tubes are hollow cylindrical structures made from a variety of materials, including steel. These tubes are used in a variety of construction projects due to their numerous advantages. In this article, we will explore the advantages of using hollow tubes in construction.

Firstly, hollow tubes are extremely strong and durable. They can

withstand high levels of pressure and stress, making them ideal for use in

construction projects. Steel hollow tubes are known for their strength and

durability, which makes them a popular choice for construction projects that

require heavy-duty support structures. Additionally, hollow tubes have a high

resistance to bending and buckling, which ensures that they remain stable even

under extreme conditions.

Secondly, hollow tubes are lightweight, making them easier to

transport and install. Compared to solid tubes, hollow tubes have a lower steel

hollow tube weight, which means they can be carried by fewer workers and

transported more easily. This makes them an ideal choice for projects where

heavy equipment cannot be used, such as in remote areas or when working in

confined spaces. Hollow tubes are also easier to cut and shape, which makes

them easier to customize to fit specific requirements.

Thirdly, hollow tubes have a low carbon footprint. They are

made from recycled materials and are 100% recyclable, which means they are an environmentally

friendly choice. Additionally, the Hollow Pipe Manufacturing Process uses less energy than the manufacturing

process of solid tubes, which further reduces their carbon footprint. As a

result, hollow tubes are becoming increasingly popular in sustainable

construction projects that aim to reduce the impact of construction on the

environment.

Fourthly, hollow tubes have a wide range of applications.

They are used in a variety of construction projects, including bridges,

buildings, and pipelines. Hollow steel pipes are commonly used in the

transportation of water and gas, while hollow steel tubes are used in the

construction of high-rise buildings and skyscrapers. Hollow tubes are also used

in the construction of structures such as wind turbines and solar panels, which

highlights their versatility.

Finally, hollow tube suppliers and hollow tube manufacturers

offer a range of sizes and specifications, which makes it easy to find the

right hollow tubes for any construction project. Whether you need hollow tubes

for a large-scale commercial project or a small-scale DIY project, there are a

variety of options available.

In conclusion, hollow tubes offer numerous advantages in

construction projects. They are strong, durable, lightweight, environmentally

friendly, versatile, and easily customizable. If you are looking for a reliable

and efficient material for your construction project, consider using hollow

tubes. There are many hollow tube suppliers and Hollow Tube Manufacturers

that can help you find the right hollow tubes for your specific needs.

Hollow tubes offer significant benefits in construction, combining strength with efficiency. Their circular cross-section provides excellent resistance to torsional and bending forces, making them ideal for structural support. Despite using less material than solid alternatives, hollow tubes maintain impressive load-bearing capabilities, reducing overall weight and cost. This lightweight nature facilitates easier transportation and installation. The hollow interior can serve multiple purposes, such as housing electrical wiring or plumbing, or being filled with concrete for added reinforcement. Additionally, hollow tubes offer improved thermal insulation properties. Their versatility of gi pipe allows for application in various architectural designs, from sleek modern structures to robust industrial facilities, making them a valuable asset in modern construction practices.

ReplyDelete